ReservationSearch and reserve rooms

Click here to confirm, change or cancel your reservation

Shinkansen accommodation plan

提携法人専用予約

2024.04.30

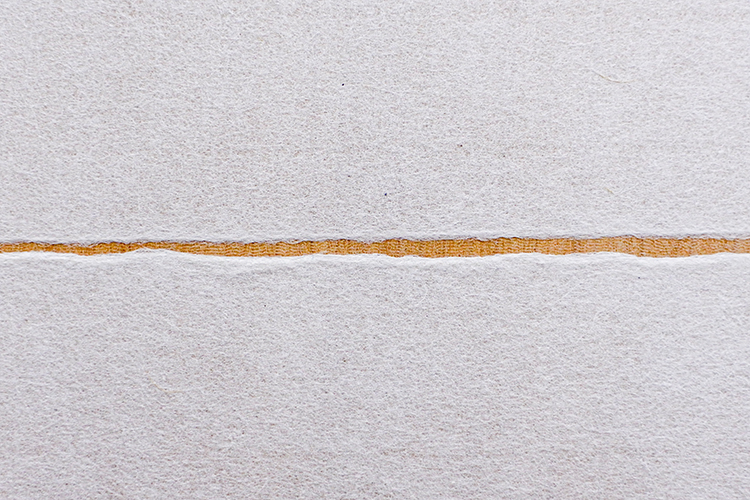

The same now as in the past. Hon-Minoshi paper is soft, strong, and translucent and beautiful.

Mino washi paper has a history of over 1,300 years in Mino City, Gifu Prefecture. The Shosoin Repository at Todaiji Temple in Nara houses the oldest paper in Japan, a paper used for family registers made in Mino. Honminoshi paper, one of the rarest types of Mino washi paper, is highly regarded for its handmade papermaking techniques and was registered as a UNESCO Intangible Cultural Property in 2014.

Beautiful, white, yet soft and strong, Honminoshi paper. We visited the workshop of Mino washi craftsman Ieda Minako, who makes this Honminoshi paper.

What is washi paper? What is Mino washi paper? What is Honminoshi paper?

Nebeshi (Tororo Aoi), the raw material for Mino washi paper

Washi paper is a type of paper that became uniquely Japanese when Chinese papermaking techniques, introduced from the continent, were adapted to suit the Japanese climate with raw materials and manufacturing methods. Western paper is made from powdered wood pulp. At the time, a lot of chemicals were used and it would fall apart after 100 years. However, washi paper is made by "filtering" the natural fibers rather than grinding them finely, and entangles them. It is highly durable because it does not lose the inherent strength of the fibers. The fact that paper that is over 1000 years old still remains is proof of this.

Mino washi refers to all types of washi paper made in Mino City, from handmade to machine-made. Handmade Mino washi is strong and durable, thin and even. This characteristic is achieved by a technique unique to Mino washi, which combines the usual "vertical rocking" with a gentle "horizontal rocking" when making the paper. And washi made in Mino City by certified craftsmen using materials and tools designated as Important Intangible Cultural Properties is called Honminoshi.

Ieda, who makes Hon Mino paper, is a rare craftsman whose skills have been recognized. The rich, high-quality water from a tributary of the Nagara River flows into his workshop, where the Daigo Nasu mulberry paper used as the papermaking material is exposed to the elements. Lined up there are tools made with Gifu's traditional techniques, including Kiso cypress papermaking mats, boats made by Gifu shipbuilders, and delicate papermaking mats. Ieda takes his time selecting the raw materials and making the paper right here.

Sukizu (papermaking mats) lined up in the workshop

"The white bark of the kozo tree, which is the raw material, is soaked in clear streams for several days to naturally bleach it and remove impurities. Then, to loosen the fibers, it is boiled in a large pot and the softened kozo is spread out under running water, and any dust and discoloration that has adhered to the fibers is carefully removed one by one. This process alone takes about a week. From there, the fibers are beaten to loosen them. After that, we add viscous "nebeshi (tororo green yam)," which helps to even out the concentration of fibers in the water, and the paper is made into paper. Nebeshi cannot be stored once mixed, so it is made in about a day. The day after it is finished, the water is squeezed out, the sheets are peeled off one by one, and dried in the sun. You can't keep doing this unless you love it," Ieda said, cheerfully describing the incredible process that goes into making Hon Minoshi.

Each and every material and process is of high quality, delicate and careful, which is what makes the paper white, even and soft to the touch. 1300 years of "unchanging" manufacturing methods and commitment. Therein lies the essence of "unchanging" Honminoshi paper.

The path to making satisfying washi paper. What emerges after long and rigorous training

To produce uniform, white washi paper, dust from the mulberry paper is carefully removed by hand.

Ieda first encountered Mino washi when he was studying Japanese painting at an art university. Normally, Japanese paintings are painted on washi paper. It is common to use Kumohada-ma-shi, a type of washi paper with a slightly uneven surface, but he encountered Mino washi in a restoration class. "My first impression of Mino washi was that it was a beautiful paper. When I held it up to the light, the fibers looked sparkling and beautiful, and I was captivated. It was like I was painting on such beautiful paper and making it dirty," he recalls.

After graduating from university, Ieda attended a school run by the Mino Washi Hall, where he learned how to make paper from raw materials. During his training, he would make seven vertical sheets (25 sheets per vertical x 7) from morning until night in the workshop. It is difficult to make 100 sheets of washi paper in the same way, as it changes depending on how the lye is removed, the season, and how the paper is shaken by the hands, and it is a natural material whose materials are not consistent to begin with. The fibers and how they are entangled are also random, so it is said that the same washi paper can never be made twice.

But Ieda-san continues to make washi paper every day. "No matter how much I make, I never reach a point where I'm satisfied with the paper. I want to continue making good paper, little by little. Every day is a training," he says with an unwavering gaze.

The techniques of Mino Washi will be protected by the craftsmen and all those involved in Mino Washi.

Washi paper with delicately intertwined fibers

Mino washi paper takes on new appeal when it is transformed from raw materials into paper for shoji screens and other products. It is important to preserve this appealing Mino washi paper for future generations. To pass on the techniques, it is important to train successors and ensure a place for Mino washi paper to be used. Raising awareness of the paper and turning it into a product may lead to the discovery of new carriers. "It is necessary for everyone involved in Mino washi paper to join hands to overcome various challenges. I have felt happy making paper for over 20 years. From now on, I would like to focus on training successors and working with paper processing companies to pass on the tradition to the future." I left the workshop touched by Ieda's desire to preserve Mino washi paper and Honminoshi paper for future generations.

The delicately intertwined world of washi paper unfolds at Ieda Paper Works' "Kaminoshigoto," a shop that specializes in washi printing and processing and sells the washi paper made by Ieda, and at Nagaragawa Department Store.

Mino Washi Paper Craftsman Minako Ieda

HP: https://www.iedashikou.com/tesukiwashi/iedaminako.html

SHOP: https://kaminoshigoto.net/, https://nagaragawa.thebase.in/

God's Work

電話:0575-38-4576

Address: 2249 Aioicho, Mino City, Gifu Prefecture, 501-3723

Access: 2 minutes walk from Gifu Bus "Nagarabashi" stop

HP: https://www.kaminoshigoto.com/

SNS: https://www.instagram.com/kaminoshigoto/

Nagaragawa Department Store (NPO ORGAN)

電話:058-269-3858

Address: 45 Minatomachi, Gifu City, Gifu Prefecture, 500-8009

Access: 2 minutes walk from Gifu Bus "Nagarabashi" stop